After constructing my initial mechanism that was outlined in the previous section, I wanted to improve upon this design. My goal of the final prototype was how I could make the motion of the mechanism more fluid and smooth from the initial design. However, since I completed the project remotely and had all of my parts shipped to me in a single batch, it would have been essentially impossible to use new parts as they would have taken extra time to ship. Because of this, there was not really much that could be improved upon when it came to the actual parts, as 3D printing is not a resource that I had access to at my convenience. However, one change I was able to make compared to the initial joint assembly improved the motion of my mechanism immensely.

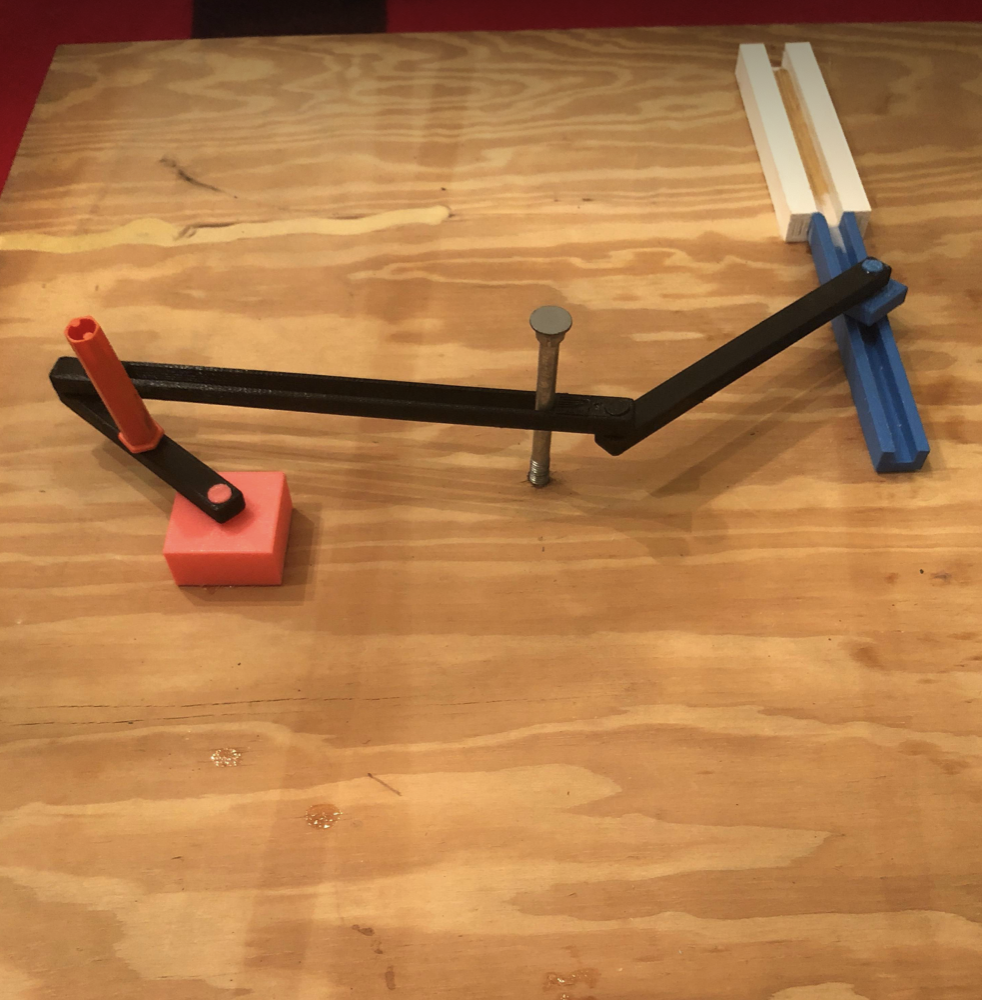

This change was attaching an orange handle into the input link which served as the hand driven crank. This orange handle had a sharp end, so I was easily able to insert it into the plastic link. Using this orange handle to drive the input link rather than just driving it myself with my hand tremendously helped the motion of my mechanism. Using the handle to drive the link caused the motion of the input link to be much more constant, smooth and refined. This new change can be seen in the photograph below, which is the final prototype:

This improved fluidity with the motion can be seen when watching this mechanism be cranked with the handle, which is the major change that the final prototype implemented. This improvement in the motion when using the handle to crank the input link rather than manually cranking it with my hand can be shown in the video of the final prototype below: