About

The Digital Fabrication lab, better known as DFAB, contains various types of equipment used in rapid prototyping and engineering design. This room houses our 3D printers, Sewing Machine, Sticker machine, Vinyl press, and mini-CNCs (Othermills). It's split into two main sections.

The first section hosts our Sewing Machine, Sticker machine, vinyl press, and Othermills. To use this equipment, contact texasinventionworks@gmail.com to be trained on the Sewing Machine, Sticker Machine plus Vinyl Press, or Othermills. Trainings for the Sewing machine, Sticker Machine plus Vinyl Press and Othermills are in person only and not guaranteed to be available due to COVID-19 restrictions.

The second section contains our advanced 3D printers, including SLA printers and Markforged Nylon printers. These machines can be used for student projects or research but are operated by only our staff. Please visit HQ or email texasinventionworks@gmail.com to inquire about starting a specialty print.

Contents |

|---|

Additive ManufacturingSubtractive Manufacturing |

CraftBot + and CraftBot XL

About

Texas Inventionworks is home to 27 White CraftBot XL 3D printers and 16 Blue CraftBot+ 3D printers. CraftBots are Fused Deposition Modeling (FDM) printers that utilize PLA and PETG filament for rapid prototyping purposes. CraftBot print quality is low compared to other staff operated printers, so for the most accurate and high-quality products, it is best to print final products on the staff operated printers.

CraftBots print 3D objects created in Computer Aided Design (CAD) software that have been sliced in a slicing software. We recommend Fusion 360 CAM software as it is FREE to download for students, easy to use, and a plethora of online video tutorials exist. CraftBots use the CraftWare slicing software to convert 3D files to .gcode files.

Access

Visit the Trainings page to complete the virtual training. Make sure you go through all the steps on the slideshow including passing the quiz and submitting a properly formatted gcode. You will be informed via email once the virtual portion of your training has been approved. To complete the 3d printing training, come to HQ in person after your virtual training has been approved. The in person training only takes 10 minutes, you will learn how to use the 3D printers and then be granted access to an online submission form. For 2020-2021, students do not start their own 3d prints. After completing training, you may submit your 3d print file virtually. You will receive an email when the print starts and later when the print finishes. If there is any errors in your print file, you will be notified via email and asked to resubmit your file.

Cost

These machines are free to use for Engineering Students, including for Research, Class, and Student Organizations.

Resources

- Make sure to consult the 3D printing Training so you understand how to properly format a 3D print file.

- It is recommended to download our staff developed CraftBot Presets for PLA and PETG.

- A link to a failed print Troubleshooting Guide.

- A link to the Fusion 360 Download. Make an account with your @utexas.edu email.

- We highly recommend viewing the Fusion 360 Video Tutorials to learn and develop your CAD skills.

| CraftBot XL | CraftBot + | ||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

| ||||||||||||||||||||||||||||||||||

Dremel 3D45 STAFF OPERATED $$$

About

Texas Inventionworks has 3 Dremel 3D45 available to print high performance Nylon, PETG, Eco-ABS, or PLA pieces with 50-micro resolution. The Dremels are FDM 3D printers, exactly like the Craftbots, using a 3D CAD model → .gcode file, but differ in their print quality. Generally speaking, the Dremels are to be used if you need a part made with a special material, have a part with a print time over 6 hours, or need a standard part with a slightly higher resolution than the CraftBots.

Access

The Dremels are staff operated. If you wish to print something on the Dremels you must bring in a .stl file, and ask a staff member on duty to start the print. You will be required to fill out a print form. You are not required to stay for the duration of the print.

Cost

The Dremel printers are not free; rather, a small fee is charged for the materials that go into operating the machine. For example, a small part the size of a contact case or a golf ball would cost around $7.

| Dremel 3D45 | |

|---|---|

| Build Volume: | 10x6.0x6.7 in 254x152.4x170.18 mm |

| Layer Resolution: | 50-300 micron |

| Filament Types: | PLA, PETG, Nylon, Eco-ABS |

| Head Max Temp: | 280 °C |

| Bed Max Temp: | 100 °C |

| Nozzle Diameter: | 0.4 mm |

Gigabot STAFF OPERATED $$$

About

Texas Inventionworks has 1 GigaBot 3+ and 1 GigaBot X (currently unavailable). The GigaBot is also a FFF printer that utilizes a 3D object → .gcode process. Use the GigaBot if you need to print very large parts or have a print that exceeds 6 hours.

Access

The GigaBot is staff operated. If you wish to print something on the GigaBot you must bring in your own filament, a .stl file, and ask a staff member on duty. You will be required to fill out a print form. You are not required to stay for the duration of the print.

Cost

These machines are free to use so long as you buy and bring in your own filament. The filament you bring in absolutely must be 2.85 mm PLA or ABS. You can find 1 kg of filament for ~ $20 on amazon.

Resources

| GigaBot | |

|---|---|

| Build Volume: | 590 x 600 x 600 mm 23.2 x 23.6 x 23.6 in. |

| Layer Resolution: | 100-300 Micron |

| Position Precision: | X,Y: 4 Micron Z: 2.5 Micron |

| Filament Diameter: | 2.85 mm |

| Bed Temp MAX: | 100 °C |

| Head Temp MAX: | 350 °C |

| Nozzle Diameter: | 0.4 mm |

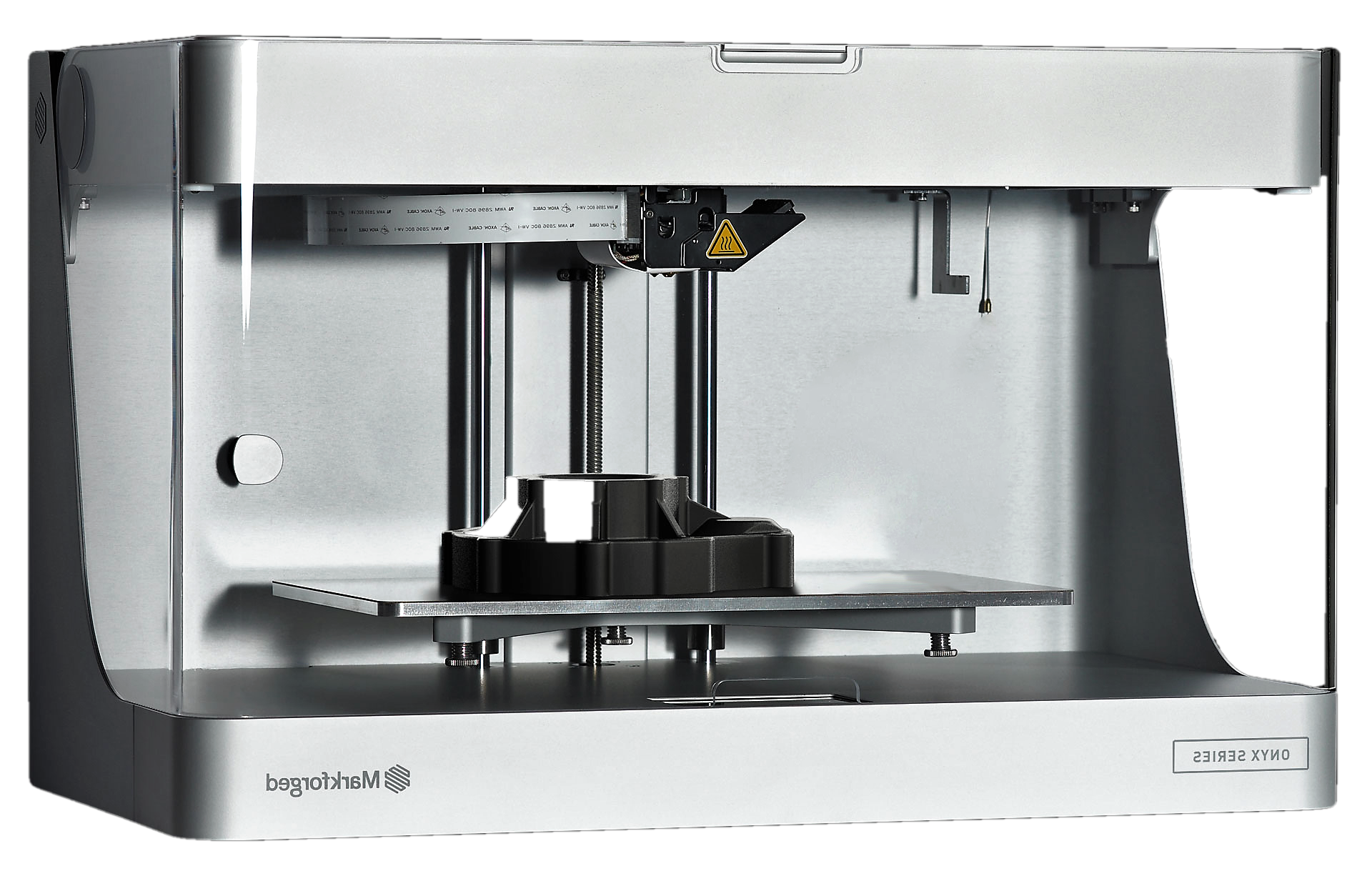

Markforged STAFF OPERATED $$$

About

Texas Inventionworks maintains three Markforged 3D pritners- 1 Onyx One and 2 Mark Twos. The Markforged printers print high-quality and high-strength engineering plastics nylon material called "Onyx" with composite inlay capabilities. Composite inlays can include carbon fiber and fiberglass While composite inlay is not required, where and how much composite you place in your part (all done with guide of a staff member) can dramatically increase strength. If you are unsure about what material settings are best for you needs, consult a staff member.

The Markforged printers are a large step up from the CraftBots in terms of quality and strength- use this machine when you need to print very strong engineering grade parts.

Access

The Markforged printers are staff operated. Please bring a .stl file to a staff member on duty to set a print up. You will be required to fill out a print form. You are not required to stay for the duration of the print.

Cost

The Markforged printers are not free; rather, a small fee is charged for the materials that go into operating the machine. For example, a small part the size of a contact case or a golf ball would cost around $7.

| Onyx One | Mark Two |

|---|---|

| Build Volume: | 320x132x154 mm 12.6x5.2x6 in |

| Layer Height: | 100 micron |

Formlabs SLA STAFF OPERATED $$$

About

Texas Inventionworks has 4 Form Labs SLA printers- 3 Form 2s and 1 Form 3. The Form Labs SLAs use Low Force Stereolithography technology to produce high resolution (25 micron) pieces with 20+ resin types. We offer a select variety of resins (but you may buy your own resin and bring it in for use if approved by Roger Rose). This printer should be used if you are looking for high surface quality or very very small parts.

Access

The From Labs printers are staff operated. Please bring a .stl file to a staff member on duty to set a print up. You will be required to fill out a print form. You are not required to stay for the duration of the print.

Cost

Similar to the Markforged printers, the From Labs printers are not free; rather, a small fee is charged for the materials and labor that go into operating the machine. For example, a small part the size of a contact case or a golf ball would cost around $7.

| Form 3 | |

|---|---|

| Build Volume: | 14.5x14.5x18.5 cm 5.7x5.7x7.3 in |

| Layer Height: | 25-300 Micron |

| Resolution: | X,Y: 25 Micron |

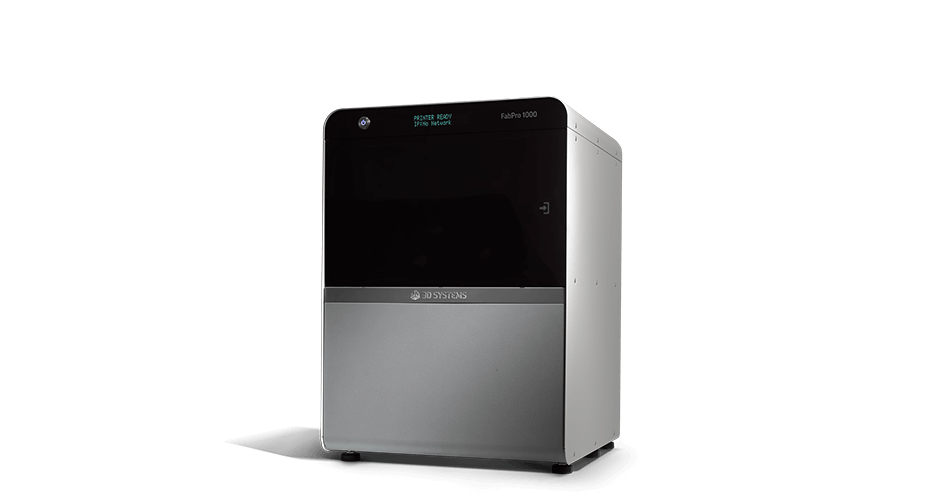

3D Systems Fab Pro 1000 SLA STAFF OPERATED $$$

About

Texas Inventionworks has 3 Fab Pro 1000 SLA Printers. These machines are much like it's SLA counter parts at it uses a digital light projector (DLP) as the light source for curing photo-reactive polymers. Texas Inventionworks carries Proto Grey, Tough Black, and Elastic Black resin. This printer should be used if you are looking for high surface quality or very very small parts made with basic materials.

Access

The Fab Pro printers are staff operated. Please bring a .stl file to a staff member on duty to set a print up. You will be required to fill out a print form. You are not required to stay for the duration of the print.

Cost

Similar to the Markforged printers and the Form Labs printers, the Fab Pros are not free; rather, a small fee is charged for the materials and labor that go into operating the machine. For example, a small part the size of a contact case or a golf ball would cost around $7.

| Fab Pro 1000 | |

Build Volume: | 125x70x120 mm or 4.92x2.76x4.72 in |

| Pixel Pitch: | 65 microns |

| Layer Thickness: | 30-100 microns (material dependent) |

Othermill Pro TRAINING REQUIRED

About

The Texas Inventionworks is home to six Othermill Pros(also known as Bantam Tools Milling Machines). Milling machines are useful tools for subtractive manufacturing- taking material AWAY from stocks. The most common uses for the Othermills are milling copper boards to produce circuit boards also known as PCBs, and milling away softer materials such as acrylic or wood to create very detailed 3D pieces.

Please note the Othermills are small Machines that are not well suited for advanced machining projects. For bigger and more advanced projects involving milling, please see the TIW Machine Shop and/or the Mechanical Engineering Machine Shop.

Access

We have Othermill PCB Training for those who wish to learn how to mill PCBs- this training involves learning how to utilize the Bantam Tools software and circuit board files such as .brd and .gbr files. This training DOES NOT include how to design circuit boards. To learn this- please refer the the materials listed under "resources."

We have a SEPARATE Othermill Milling Training for those who wish to mill other materials such as wood, acrylic, and soft metals. This training involves learning how to utilize the Fusion 360 Computer Aided Manufacturing (CAM) software and Bantam Tools Software. Please note that this training goes over very basic CAM software; if you wish to obtain an advanced CAM skill-set, please refer to to the materials listed under "resources."

Please note that the 2 milling trainings are mutually exclusive and independent- you cannot receive both in one training, but one is not required for the other. To sign up for these trainings, inquire in-person at HQ or email texasinventionworks@gmail.com.

Cost

It is FREE to use the Othermills so long as you have training. We sell single and double sided PCB boards ($0.75/$1.00) for PCB milling, but if you wish to mill anything else, you must bring in stock of your own.

- DO USE materials such as FR-1 PCB Blanks, Acrylic, Machining Max, Linoleum, Aluminum, Wood, ABS, Poly-carbonate, etc.

- DO NOT USE Fiberglass PCB Blanks, Heavy Metals (including Lead), Solid Copper, Steel, Titanium, Glass, Carbon Nano Fiber, etc.

Resources

- Autodesk's FREE Eagle PCB design Software and Tutorials.

- Autodesk's FREE Fusion 360 Software and CAM Tutorials.

- Bantam Tool's Resources .

- Eagle PCB Deisgn Reference Guide.

- **Super Easy to Follow PCB Design Guide using Eagle.**

- Othermill 360 CAM Reference Guide.

| Othermill Pro | |

|---|---|

| Cutting Area: | 140×114×34.3 mm 5.5×4.5×1.35 in |