What is the UT Robotics Lab

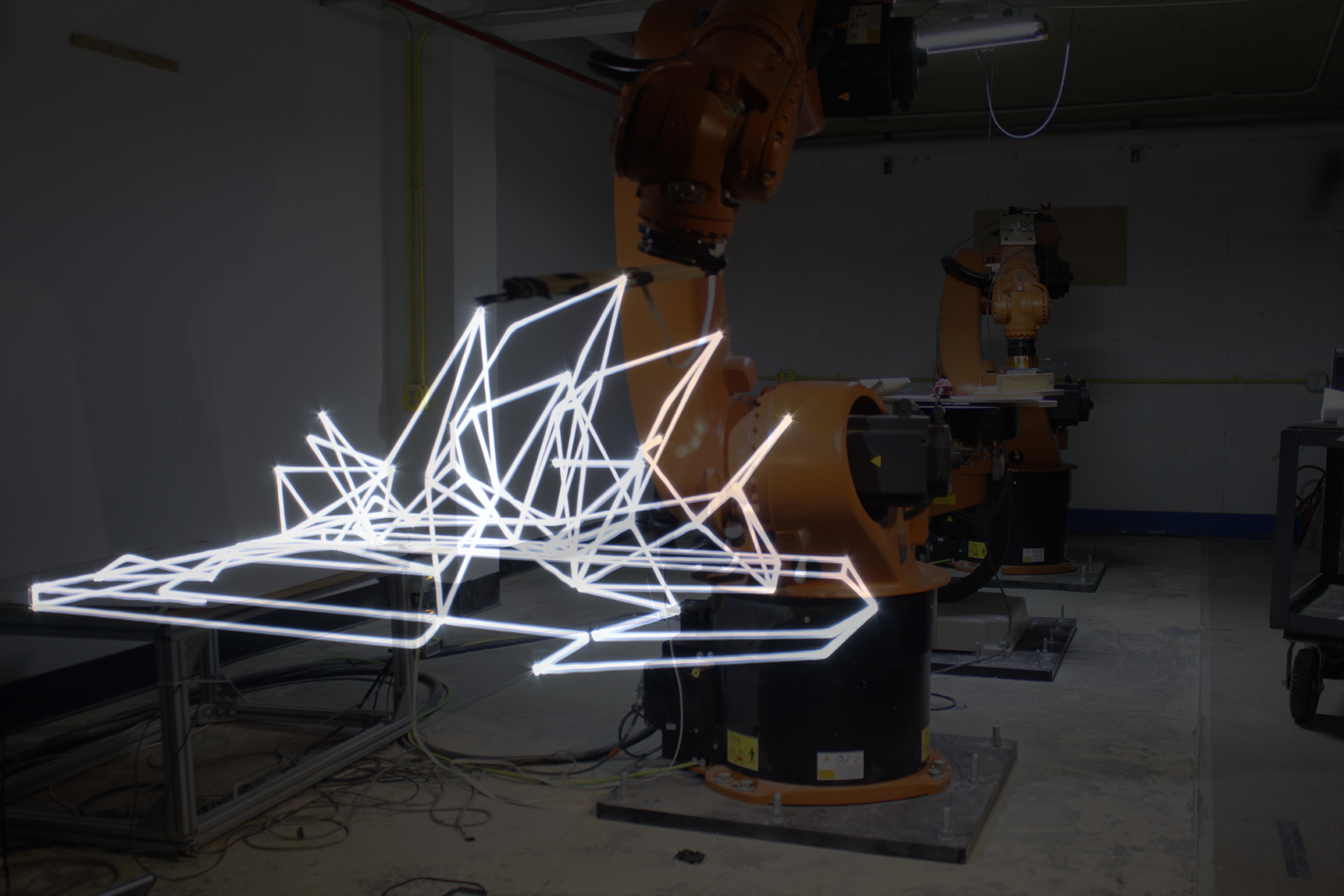

The UT Robotics Lab is a place for creative exploration and practical realization of advanced digital fabrication methods. We work to foster an environment of curious exploration and offer a wide array of tools and support for UT students, faculty, and staff to realize their creative interests! Using Kuka Kr60 industrial robot arms and a DKP400 two-axis positioner, the robotics lab is equipped to handle a variety of tasks both immediately or with a simple tool change.

What We Do

At the UT Robotics Lab, through our continuous research into robotics and design, we have developed various custom tools and work-flows using a variety of scripting languages such as Grasshopper, Python, VBA, C# and others in order to develop the following tools that are available immediately upon request:

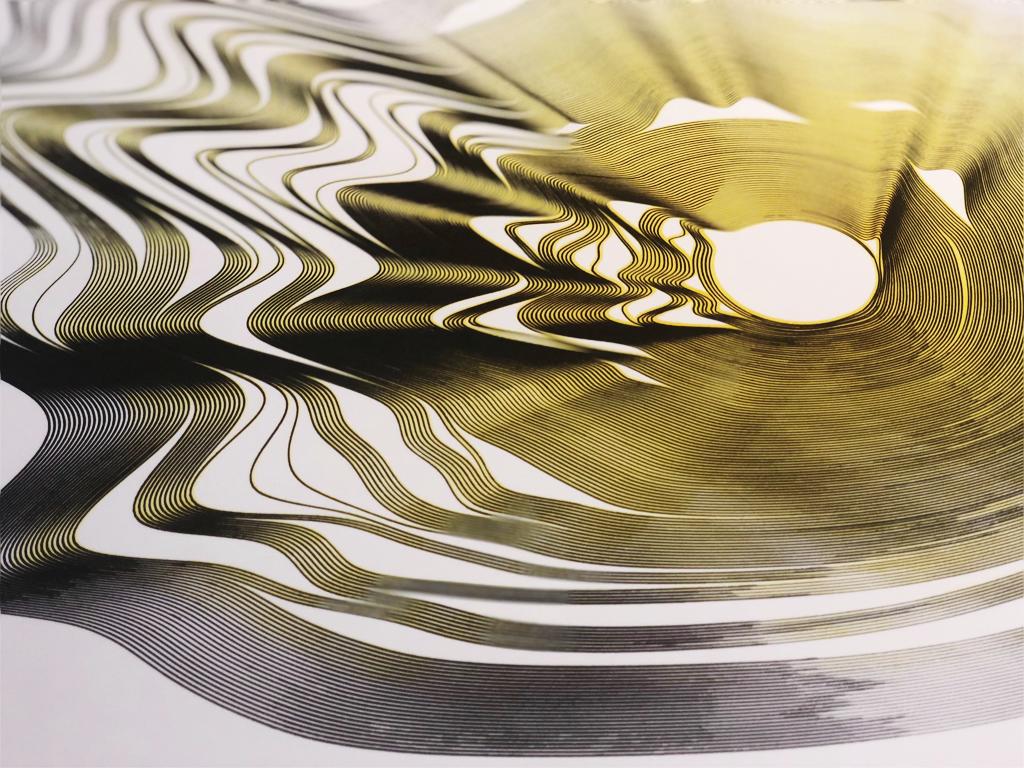

- Drawing

- Extruding

- Dabbing

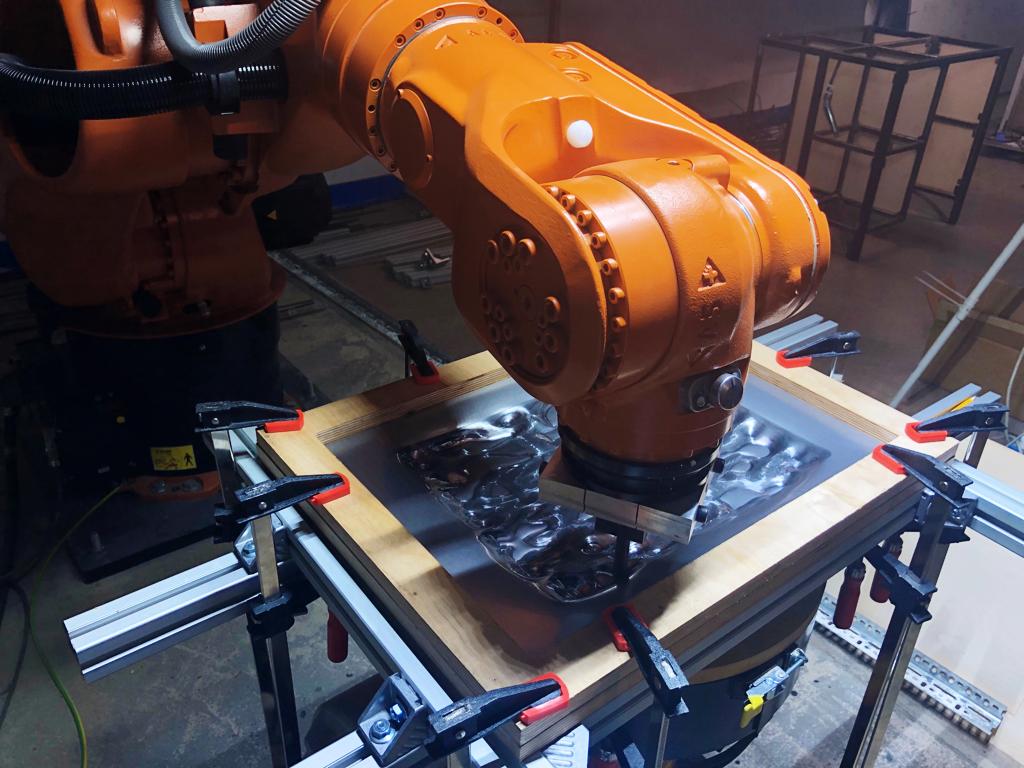

- Incremental Metal Forming

The Process is simple! We program the robot using the KUKA PRC plugin for grasshopper to produce a set of toolpaths to follow. Each task has its own pre-dedicated workspace which allows the KUKA PRC to translate virtual space in Rhino 3D to the real world setup. Instead of writing code, simple function-blocks are connected with each other and the results immediately visualized. This instantaneous feedback allows the acceleration of the process from the programming environment to the robot, or from design to fabrication. Our currently developed KUKA PRC process accepts MESHES and LINES and can be used with some of the Tools we have extensively worked with. Some additional tools available to all faculty and students with a minor lead time for tool changing and preparation:

- Rod bending

- Heat gun forming

Milling

Gripper functions

The versatility of the Robots allows for a simple tool change for the head of the robot that would transform it into a totally different machine. We custom make our own tools which adds an extra level of versatility to what exactly we can use the robots for. This customization pushes us forward to test new setups and apparatus as a part of our continuous research effort that seeks to blur the line between Robots and Design.

Incremental Metal Forming Heat Gun Forming Rod Bending Wood Milling

Current research includes dabbing drawing processes for architectural materials as well as developing complex resin castings to form unique and unusual objects. Our multidisciplinary team includes students from Architecture, Sustainable Design, and Electrical Engineering which means someone from almost any background can bring something unique to the table!

Exhibition (1) Exhibition (2) Multilayered Pen Drawing

So you want to work with robots?

If you are interested in completing projects with the robots, please speak with a professor and ask them to reach out to the Technology Lab to discuss your project(soatechdesk@utexas.edu)