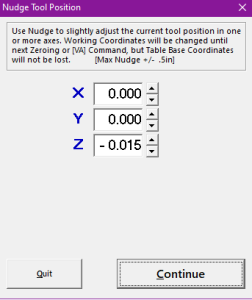

Your print is not cutting through to the desired depth; this can be caused by a file issue, tool tip calibration or a worn table surface. If you experience any of these issues please send an email to soatechdesk@utexas.edu to ensure that a staff member is aware of machine or table damage. Proceed with caution when using the NUDGE command. Any damage to the spoil board should be reported so that it may be addressed prior to the next CNC user. The goal is to cut 100% through your material and not to go deeper than 1/32 of an inch into the spoil board. Proceed to CNC Troubleshooting | Router | Resuming a stopped job if you recorded the Line # that your job stopped on.Problem

Solution

Overview

Content Tools