As mentioned previously, I went through several iterations of the design before settling on the final design that met my requirements. My first iteration did not even involve a geared five-bar linkage - it was a simpler four-bar linkage, with a similar spinning platter for the paper as the final design. The spinning platter in this design was coupled directly to the input of the four-bar linkage via two gears, meaning that the motions of the platter and the input link were always in phase. In my prototype of this design, the gear of the input link and the gear of the platter had a 1:3 ratio, resulting in the motion seen in the video below. I suspect that for gear ratios where neither number is 1, the motion would be slightly more complex, and the end of the line drawn by the pen would take much longer to meet back with the start.

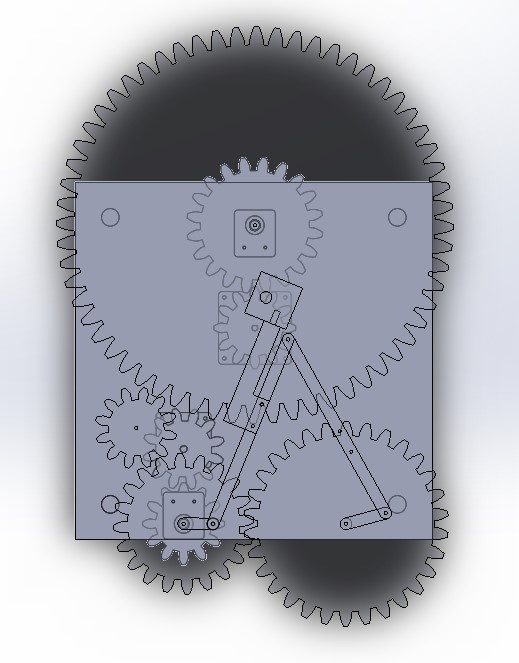

In the end, I decided that the pattern produced by this mechanism was not interesting enough, so I moved to the next iteration of the design (still using the four-bar linkage). A CAD model of this iteration can be seen in Fig. 5. I thought that by decreasing the gear ratio between the input gear and the platter, I would be able to slow down the rotation of the platter and create a more complex design. Thus, this iteration involved a geartrain, which would have resulted in a 4:25 reduction in angular speed from the input gear to the platter. At this point, the mechanism seemed a little too complex, and the geartrain was taking up too much space. Thus, to increase the complexity of the mechanism's movement without too many added parts, I settled on the geared five-bar linkage seen in the final mechanism.

Figure 5. CAD model of the second prototype iteration.

Figure 5. CAD model of the second prototype iteration.

For the final mechanism, the platter was a 60-tooth gear to which a piece of paper could be fixed, and the input arms were connected to a 20- and 30-tooth gear for the geared five-bar linkage. Most of the gears were laser-cut out of 3mm thick acrylic, with a few gears made laser-cut with 3mm thick plywood. I chose these materials since they were easily accessible for free at Texas InventionWorks (TIW), and I decided on using acrylic for the majority of the mechanism since it does not splinter like plywood does when machined (although cracking turned out to be a slight concern later on). The gears and linkage were fixed to a 1ft x 1ft piece of acrylic for structural rigidity. To solve the issue of the platter not spinning slow enough, a stepper motor was used to drive the platter in the final mechanism. Although this does not align with the initial project goal of creating a 1-DoF mechanism, it enabled far more customization and simplified the building process significantly.

Figure 6. CAD model of final mechanism.

The driven gears in the final mechanism were fixed to the ends of driveshafts mounted in bearing blocks for freedom of movement. The driveshafts were 8mm diameter wooden dowels, found in TIW, which fit snugly into the sealed ball bearings. Two motors, a 12v DC motor geared to run at a nominal speed of 100 RPM and a NEMA 17 stepper motor, were used to drive the mechanism. The 12v DC motor was used to drive the linkage, and it was connected to the driveshaft through two more laser-cut gears. During testing, a DC lab bench power supply was used to run the DC motor at a reduced speed and voltage, so the pen would be able to write smoothly. (I considered using a motor driver and PWM to drive this motor, but since I was already using a motor driver and Arduino to drive the stepper, it seemed unnecessarily complicated.) Both motors were mounted in laser-cut acrylic brackets, which in turn were mounted onto a second 1ft x 1ft sheet of acrylic at the bottom of the mechanism using more wooden dowels. All the fixed connections throughout the mechanism were made using M3 bolts and nuts, since they were readily available at TIW. Non-driven gears were mounted the same way. (I later found that since the nuts were not fixed to the ends of the bolts, they sometimes loosened themselves and fell out while the mechanism was running. A more permanent solution would have been to Loctite the nuts to the ends of the bolts, or to use another type of shaft entirely, but I felt that the ease of disassembly was more of a benefit than a drawback during the construction of the mechanism.) Where possible, holes were drilled slightly smaller than the outer diameter of the bolts, so that they could be threaded directly into the acrylic/wood.

Figure 7. CAD model of mount for stepper motor.

Figure 8. CAD model of drivetrain assembly.

Initially, my plan was to use belts instead of gears to link the gears and the motors. This would have allowed the mechanism to move more smoothly, provided the belt tension was enough to keep it from slipping. The belts would have been mounted on pulleys made of laser-cut acrylic, and the belts themselves were to be rubber bands found at TIW. However, due to challenges detailed in the Manufacturing and Assembly section, the decision was made to switch to using gears instead. A 1:1 gear ratio was used for the DC motor, and a 3:5 ratio was used for the stepper in an attempt to reduce the effect of the stepper vibrating during operation. The entire drivetrain assembly was mounted on the bottom sheet of acrylic, which itself was bonded to the upper sheet of acrylic through four wooden dowels using hot glue and bolts.

The pen was pressed into a wooden block, chosen because of easy access and machinability, inside a hole drilled slightly larger than the diameter of the pen which held it in place. The weight of the pen and wooden block combined was enough to mostly keep contact with the pen tip and paper, provided the speed of the input link was low enough. The block was fixed to link 3 of the mechanism using a laser-cut piece of acrylic, one end of which was mounted to link 3 using bolts and nuts, and the other end of which was inserted into a second hole drilled into the side of the wooden block and secured using hot glue.

Figure 9. Pen holder assembly.

To enable further customization, a series of eight evenly-spaced holes were drilled in a circular pattern into the two gears of the five-bar linkage. The two input links were bolted to these holes to fix their rotation to match those of the gears. Using these holes, the phase angle between the two input links could be adjusted in 45-degree intervals. Additionally, an element from the first prototype was incorporated to the final mechanism: a 12-tooth gear could be placed between the driving 20-tooth gear and the platter (60-tooth gear), effectively creating a 1:3 gear ratio between the input gear and the platter, just like the prototype. When using this configuration, the mechanism becomes a 1-DoF mechanism, with the stepper motor deactivated and only the DC motor driving the entire mechanism. A final bit of customization could be achieved by removing the 30-tooth gear entirely and fixing the second input arm to the acrylic backplate, effectively turning the mechanism into a standard four-bar mechanism. Some of these customization options are explored in the Final Prototype section.

Figure 10. Holes drilled into the input gears.

Figure 10. Holes drilled into the input gears.

To solve the issue of the heads of the bolts interfering with the action of the linkage, spacers were created from acrylic and wood to keep the links rotating above the height of the bolt heads.