Sections of this Document

Operation

Standard Cuts

Refer to owner's manual for complete operational instructions. SawStop_PCS Owners Manual Model PCS31230 V5.0 09-13.pdf | |

Power on Saw SystemEnsure Start/Stop paddle is "OFF" (pushed in) Turn Main Power Switch "ON" - system will self-check (5-10 sec.) LED displays "READY" (Green On, Red Off) |  |

Adjusting Blade HeightFor through cuts, the blade height should be no more than 1/8-inch - 1/2-inch above the workpiece Loosen the elevation lockknob Turn the elevation handwheel until theblade is at the desired height Turn the handwheel clockwise to raise the blade, and counter-clockwise to lower the blade. Lock the blade height by turning the elevation lock knob clockwise until tight. |  |

Adjusting the Blade TiltThe tilt (bevel) angle of the blade can be adjustedbetween 0° and 45° Loosen the tilt lock knob Turn the tilt handwheel until the blade is at the desired angle. Turn the tilt handwheel counter-clockwise to increase the tilt angle, andclockwise to decrease the tilt angle. Lock the tilt angle by turning the tilt lock knob clockwise until tight. |  |

Start MotorPull Start/Stop paddle out | |

Stop MotorPush Start/Stop paddle in | |

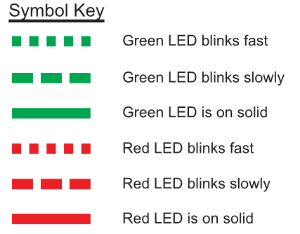

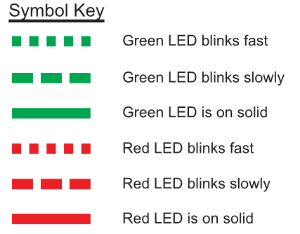

System Status Codes |   |

Frequently Asked Questions

How does the SawStop Safety System Work?

SawStop Saws Detect Contact With Skin. The blade carries a small electrical signal, which the safety system continually monitors. When skin contacts the blade, the signal changes because the human body is conductive. The change to the signal activates the safety system.

Upon activation of the safety system, an aluminum brake springs into the spinning blade, stopping it in less than 5 milliseconds! The blade’s angular momentum drives it beneath the table, removing the risk of subsequent contact. Power to the motor is shut off.

Can I get a serious injury using a SawStop saw?

In the vast majority of cases, coming in contact with the spinning blade will result in a minor cut. However, if your hand moves into the blade at very high speed, it is possible for you to receive a serious injury.

How can I be certain the safety system is working?

The SawStop safety system continuously performs many self-checks to ensure the components of the safety system are working properly. The safety system will not allow the motor to start (or to remain running) unless every component of the safety system is working properly.

What if I am wearing gloves when cutting? Will the safety system still work?

Do not wear gloves when using a SawStop saw because the glove can snag on the blade and pull your hand into the blade at high velocity. The safety system will still react as soon as your skin contacts the blade, but the resulting injury can be more severe because of the velocity of your hand.

What if I am wearing gloves when cutting? Will the safety system still work?

Do not wear gloves when using a SawStop saw because the glove can snag on the blade and pull your hand into the blade at high velocity. The safety system will still react as soon as your skin contacts the blade, but the resulting injury can be more severe because of the velocity of your hand.

What do I do if I activate the safety system's brake cartridge? What will it cost to reset the safety system? Does activation damage the saw?

If you activate the safety system’s brake, you will need to replace the brake cartridge and evaluate the condition of the blade for future use. Replacing the brake cartridge is simple and can take as little as 90 seconds to complete. A standard brake cartridge costs $69 USD and a dado brake cartridge $89 USD. SawStop saws are designed to absorb the force of activation and are not damaged by it.

Do I need to use a blade guard with a SawStop saw?

Yes. SawStop strongly recommends that you use a blade guard whenever possible.

Will cutting green or "wet" wood activate the SawStop safety system?

SawStop saws cut most wet wood without a problem. However, if the wood is very green or wet (for example, wet enough to spray a mist when cutting), or if the wood is both wet and pressure treated, then the wood may be sufficiently conductive to activate the brake. If you are unsure whether the material you need to cut is conductive, you can make test cuts using Bypass Mode to determine if it will activate the safety system’s brake. The red light on the control box will flash to indicate conductivity.

Can I cut conductive materials?

Yes. You can operate the saw in Bypass Mode which deactivates the safety system’s braking feature, allowing you to cut aluminum, very wet/green wood (see above) and other known conductive materials.

Is there a way to check if a material is conductive before I cut?

If you are unsure whether the material you need to cut is conductive, you can make test cuts using Bypass Mode to determine if it will activate the safety system’s brake. The red light on the control box will flash to indicate conductivity.

Part #'s, Specs & Operation Manuals